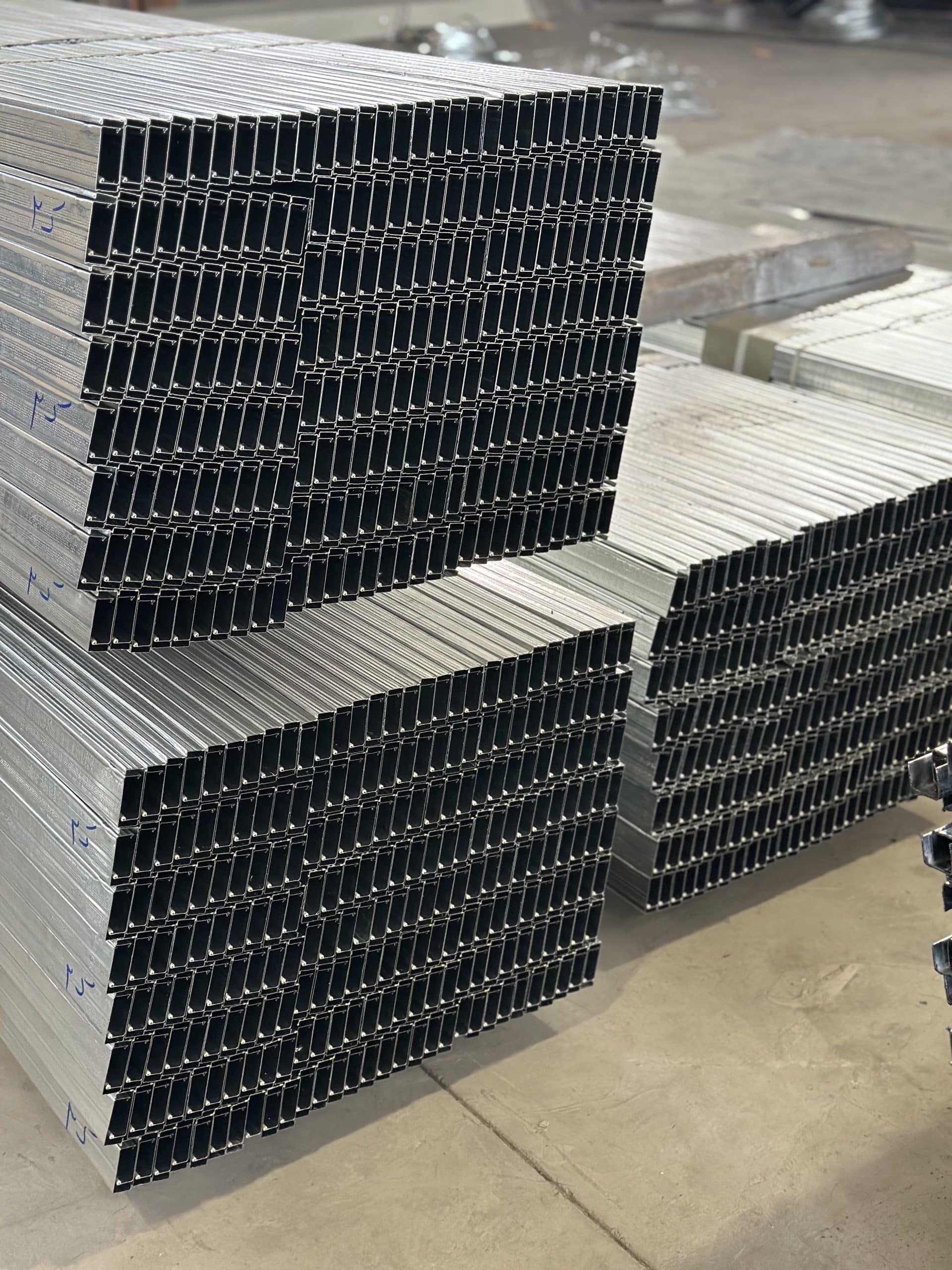

galvanized

As you know, UPVC door and window is a product that 85% of it is made of plastic, so it does not have the ability to bear weight and high pressure, and to solve this problem, a solution has been provided, which is the use of galvanization. Galvanized works like bones and spine in the body. By using galvanization in UPVC windows, the strength and resistance of these windows is greatly increased and profile deformation is prevented.

Practically galvanized, it is used to prevent distortion, tension, warping and finally strengthen the profile of uPVC door and window.

Galvanized pattern in the window

One of the most important issues in the production of UPVC doors and windows is the strength and resistance of the profile. Galvanizing increases the strength of the profile and makes it resistant to tilting and deformation. In determining and choosing the right galvanized for UPVC doors and windows, the following important points should be observed.

- Galvanizing should be used in a completely integrated way along the entire length of the cross-section of the profile.

Some manufacturers of UPVC doors and windows use the inside profile of the window in order to lower their production costs and earn more profit. This will cause your windows to be distorted over time. According to the requirements defined by most of the profile manufacturers, the use of galvanized steel from the first to the fifth floors in normal dimensions and heights should be 1.25 mm thick, and from the sixth to twenty-fifth floors, according to the dimensions and height of the window, galvanized steel should be 1.5 mm or sometimes in some special cases 2 mm thickness should be used. - The next item regarding windows that are used at high altitudes and larger dimensions, or in areas with high wind speed and air pressure changes, the thickness and cross section of the galvanized should be calculated, which is done by most of the door and door manufacturers. The windows are oblivious to it.

- The galvanized used in the UPVC profile must be connected to the body of the UPVC profile with standard screws every 15 cm from the beginning and end of the profile, as well as at a maximum distance of 40 cm between the screws. This is a standard defined in the uPVC industry, whether the manufacturers follow it or not, is something that today’s employers should be aware of and ask the manufacturer to do so.

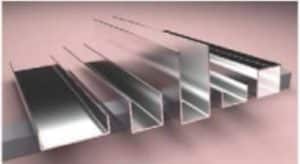

Types of galvanized in terms of thickness

Note that you should consider the appropriate cross-section and dimensions according to the part you want to use galvanized, which we talk about in the detailed profile reading catalog. Since the cross-sectional area of the UPVC profile in the doors is larger than the profile of the windows, so their inner chamber is also larger. This case makes the galvanized dimensions used in the doors to be much larger than the dimensions used in the windows.

It is better to use CRP in a crescent or bent window, which is not a part of the profile that is flat and angular, which can be a suitable alternative in bent or crescent profiles.

Galvanized sheets are produced in thicknesses of 1.25, 1.5 and 2 mm and are selected and produced according to the installation height and air pressure. According to the investigation and calculations done on the force applied to the door and window and the amount of load on them, the galvanized manufacturing companies offer different thicknesses to the market, which is galvanized with a thickness of at least 1.25 mm approved by most of the profile manufacturers. and door and window assemblers.

But the point that we should not ignore is that nowadays even thicknesses of 0.7, 0.8, 0.9 and 1 mm are produced by galvanized manufacturers according to the request of the assemblers, which does not have the required standard and only the production cost of that production. Reduces the door and window.

Naturally, if this issue comes to the knowledge of the customer, there is no problem, because the reduction of the production cost will be transferred to the customer and respected employers. but if ……….

How to produce galvanized UPVC window

Galvanized is produced from metal sheets that have a zinc coating. This coating is combined with galvanization and is not separated from its surface in any way. Sheet rolls produced in galvanized sheet factories, after being transferred to profile manufacturers, are first cut to the appropriate dimensions and then using rolling machines in U shape, or C shape, square shape or can and L shape. And it is formed at different levels.

The quality of this product is controlled in all production processes so that we have galvanization with the same thickness throughout the length of the profile.

Galvanized evaluation criteria

• Galvanized shape and dimensions

• External pressures on doors and windows

• The location of the window or door and the amount of opening and closing and its use

• Door or window installation location in terms of security

• Opening weight

It should be noted that galvanized profiles have different shapes and each of these shapes has a direct dependence on the type, shape and technical specifications of the profile, these shapes can be regular or irregular depending on the type of profile. Its thickness is variable and depends on the place of use of the window, and usually every manufacturer provides its special information, and we talk about this information in detail in the profile reading catalog.

Galvanized test

The existence of galvanization in UPVC doors and windows is a vital matter. Unfortunately, some manufacturers of doors and windows do not use galvanization in their products and use it only in the points where the connector or hinge screw is closed. This has caused your window to deform over time. One of the ways we can test whether galvanized doors and windows have been used or not is to use a strong magnet. We stick the magnet on the profile, if the magnet is attracted, it is galvanized inside the profile, and if not, another way is to see whether the galvanized screw is worked on the back of the frame and on the hinge.

What happens if you don’t use galvanized?

If galvanized is not used in the uPVC window, after installing the door and window in a short period of time when the window is exposed to direct sunlight, they will be warped and warped and the insulation of the openings will be very weak. The fittings will wear out over time and will not be able to hold a sheet that is not galvanized.

Partitions or mullions, unlike frames and frames that are welded with plastic, they are installed inside the window with screws, and these screws must penetrate the galvanization, and the lack of galvanization causes the partitions or mullions to move from their place. and the window loses its insulation over time.