What criteria should be considered in choosing galvanized?

In response to this question, some interesting justifications are provided by some galvanized or window manufacturers, which are evident in some kind of intentional or unintentional profit-seeking, including the following:

- A galvanized type with the same dimensions or thickness can be used for all profiles.

- By equalizing the dimensions and thickness of galvanized for all profiles, the cost of storage is reduced!

- In openings, it is enough to use galvanized belt alone, and even in the place of door or window handle installation, there is no need to use galvanized!

But before answering these ambiguities, we must first answer the question of what static or dynamic loads are directly or indirectly applied to the window, so that we can answer the question of what loads galvanizing should resist. to give

The total loads entering the window can be divided into four general sections, each of which has the following subsets:

1. The external factors of the building include:

1. Wind, rain and temperature changes throughout the day and year

2. Acoustic

3. Physical pressures such as theft

4. Light and amount of UV radiation

2. Architectural factors include:

1- Tolerance

2- Meeting of the building

3. Internal (building) factors such as humidity or temperature inside the room

4. Factors directly related to the window itself include:

a. Expansion, shape changes, dead load

b. Incoming forces during opening and closing

c. Sudden forces (impact, earthquake, etc.)

d. The weight of the openings

In the next step, we should check what role galvanization plays in the upvc double-glazed window.

These include:

– Increasing profile endurance

– Bearing weight

-Torque transmission

– Increasing security

– Wind pressure

By combining these two issues, the evaluation criteria for galvanized can be achieved. These criteria are respectively:

- Galvanized shape and dimensions

- External pressure on the window (such as wind, rain, etc.)

- The place of application of the window or door and the amount of opening and closing and its use (public places, offices or homes)

- Door or window installation location in terms of security

- Opening weight

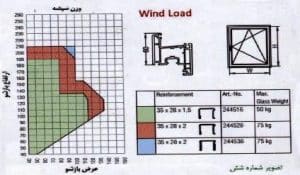

The thickness of these galvanizations is variable and depends on the place of use of the window, and usually every manufacturer has provided its special information. For example, in the image below, you can see some of these calculations and their moments for a specific profile

Usually, the supplier of the profile produces a technical manual for ease of work and to avoid complex calculations.

This booklet contains tables similar to picture number 6, which can be calculated based on weight, wind pressure, galvanized shape and thickness. Of course, these calculation tables have been calculated for normal windows with basic security, and calculations must be done accurately in special conditions. But in general, they are very useful for the convenience and acceleration of calculations of the thickness and shape of galvanized steel, and it is definitely recommended to refer to them.

Also, some profile manufacturing companies have dedicated software that calculates the thickness and type of galvanizing based on their general information. Some famous European software also have this capability.

Regarding other windows that have administrative, commercial or security applications, the conditions are not as easy to calculate as public windows, especially in security windows. In this situation, in addition to the criteria proposed so far, the specifications of the fittings are also directly discussed in this matter, and even the way of placing the galvanized inside the profile may change.

Now, with these attributes, the following doubts can be definitively answered:

1) The first ambiguity:

For all profiles, a galvanized type with the same dimensions or thickness can be used!

According to what was mentioned, even for a profile with a specific series, the conditions for choosing galvanized are subject to factors such as wind pressure, window weight, glass weight, type of fittings, installation height, type of window application (residential, commercial) and… Therefore, it is unacceptable to be able to use the same galvanized shape and thickness for all profiles (brand, series, type of profile: opening, mullion and frame).

Note: If you are faced with limited storage and do not have the possibility of having different thicknesses, you can choose one or two thicknesses with a reliability factor based on the worst conditions and use it for your projects.

2) The second ambiguity:

By equalizing the dimensions and thickness of galvanized for all profiles, the cost of storage is reduced!

It is wrong to think that using the same type of galvanization with the same shape and thickness for all profiles can reduce storage costs, as you definitely cannot order all profiles as frames instead of ordering frame, opening and mullin profiles. You can’t do this with galvanized.

But why such an idea is spread in the society, maybe we should look for it in galvanized suppliers, obviously, if the window manufacturers all order the same thickness and shape, the cost and time of adjusting the rolling machines will be reduced and more profit will be made. It will become the producers and at the same time it will justify the warehousing and warehousing profit, but at what price?

However, many suppliers of galvanized profiles are overshadowed by these issues and always offer sympathetic advice to window and door manufacturers and assemblers.

3) The third ambiguity:

The use of the hinge belt makes us unnecessary to use galvanized in the opening profile!

Some window manufacturers deliberately or inadvertently put forward arguments about the phenomenon called strap and hinge and claim that if it is used, there is no need to galvanize the opening, this claim is also baseless and its purpose The only price reduction is the finished price of the window, but again the question is at what price?

Each square meter of double-glazed glass has a weight between 25 and 35 kg, and it is impossible to imagine that the upvc profile alone can withstand it, maybe the opening can withstand this weight for a while, but definitely a phenomenon such as profile deformation and its shape change Within one to two years (depending on the dimensions, pressure and weight of the double-glazed glass), they will be definitive, and soon this window will lose its ability to seal and air-tight. But what makes the issue more sensitive is that it is more likely to happen in a longer period and will be lurking in a way for the consumer of this window:

There is a possibility that the profile will be separated or broken from the welding places or the profile itself and the glass will be separated from it, which will certainly cause life risks if it falls on someone with that weight. Unfortunately, several such cases have happened so far, and according to the author’s knowledge, two children have also died due to the fall of the double-glazed glass, and of course, in the prosecution, a verdict of manslaughter has been issued in this case.

According to the information presented above, we can say that we do not have a suitable substitute for galvanizing and the information about CRP profile is not completely realistic. Even in the use of galvanizing, the necessary standards and methods Consider consumption and choice of thickness.